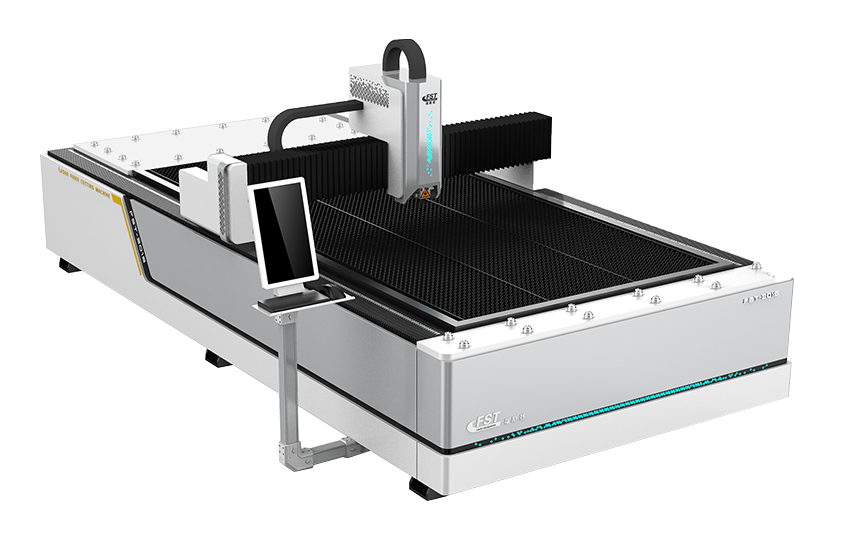

Ka mmepe ụlọ ọrụ na-aga n'ihu ngwa ngwa.eriri laser ọnwụ igweachọtala ngwa zuru oke. Otú ọ dị, mgbe ejiri ogologo oge mee ihe, nkwụsị nke igwe ndị a nwere ike ịnweta mgbanwe ụfọdụ, na-ebute ngwaahịa ndị nwere ike ọ gaghị ezute ụkpụrụ achọrọ. A na-ebutekarị ihe nhụsianya ndị a site na okwu nwere ogologo isi n'uche. Ya mere, ọ dị oké mkpa ịghọta otú e si calibrate nbibi ziri ezi nke laser ọnwụ igwe. N'ebe a, anyị ga-enyocha ụzọ maka ịhazi nhazi nke ọma nke fiber laser ọnwụ igwe.

Mgbe a na-edozi ntụpọ laser ka ọ dị ntakịrị, mee nyocha ntụpọ iji guzobe mmetụta mbụ. Enwere ike ikpebi ọnọdụ a na-elekwasị anya site n'ịtụle nha nke ntụpọ laser. Ozugbo ntụpọ laser rutere nha kacha nta, ọnọdụ a na-anọchite anya ogologo nhazi nhazi kachasị mma, ma ị nwere ike ịga n'ihu na usoro nhazi.

Na mmalite nkebi nkelaser ọnwụ igwecalibration, ị nwere ike iji ụfọdụ akwụkwọ nyocha ma ọ bụ ihe mkpofu iji mee nyocha ntụpọ ma chọpụta izi ezi nke ọnọdụ ebe ahụ. Site n'ịgbanwe ịdị elu nke isi laser elu na ala, nha nke ntụpọ laser ga-adịgasị iche n'oge ule ntụpọ. Ndozigharị ugboro ugboro na ọnọdụ dị iche iche ga-enyere gị aka ịmata ebe kachasị nta nke laser, na-enye gị ohere ikpebi ogologo ebe kachasị mma na ọnọdụ kachasị mma maka isi laser.

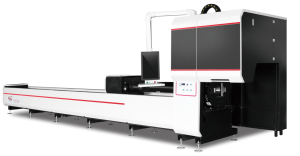

Mgbe echichi nkeeriri laser ọnwụ igwe, A na-etinye ihe eji ede ihe na nozzle nke igwe ịkpụ CNC. A na-eji ngwaọrụ a edepụta usoro igbutu simulated, nke bụ square mita 1 nke edere okirikiri nke dayameta 1 mita n'ime ya. Edebere ahịrị diagonal site na nkuku nke square ahụ. Ozugbo edechara, a na-eji ngwaọrụ nha iji chọpụta ma okirikiri ahụ ọ na-aga n'akụkụ anọ nke square ahụ. Ogologo diagonal nke square ahụ kwesịrị ịbụ √2 mita, na etiti etiti nke gburugburu kwesịrị bisect akụkụ nke square ahụ. Ebe ebe etiti etiti na-agafe akụkụ square kwesịrị ịdị 0,5 mita site na nkuku nke square ahụ. Site n'ịleta anya n'etiti diagonals na ebe nkwụsịtụ, enwere ike ikpebi ịkpụzi ngwa ngwa.

Oge nzipu: Ọgọst-20-2024